What is it about?

In the apparel industry, the overall seam quality is defined by various functional and aesthetic performances desired for the apparel product during its end use. The performance and quality of seams depend on various factors, such as seam strength, slippage, puckering, appearance, and yarn severance. The objective of this study is to investigate and compare the effects of fabric composition, sewing direction, sewing thread type, needle size, stitch density, and repeated washing cycles on the seam strength and seam pucker of knitted fabrics. For this purpose, knitted fabrics of 100% cotton, 100% viscose, 100% polyester, and their blends with elastane were produced with different masses. The specimens were sewn with different sewing parameters. Then, seam strength and seam pucker values of the sewn specimens were measured before and after ten repeated washing cycles. The data were used to analyze the factors affecting the seam quality.

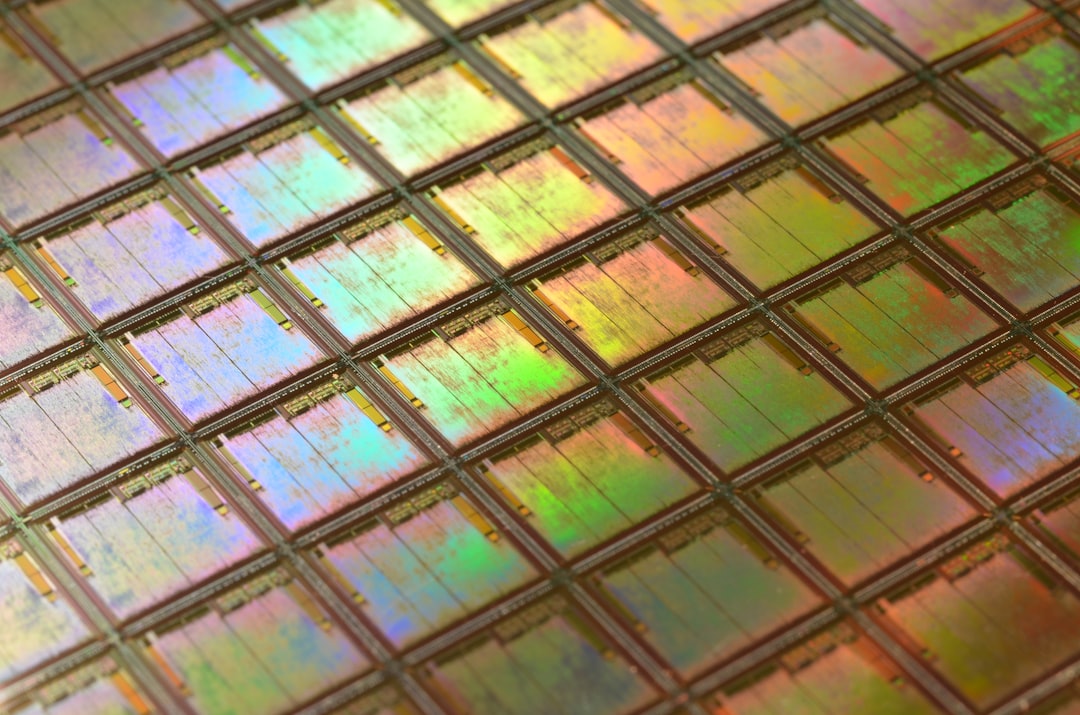

Featured Image

Photo by SUNBEAM PHOTOGRAPHY on Unsplash

Why is it important?

The seam is one of the basic requirements for the production of garments. The performance and appearance of seams are important components of the quality of the final product. Most studies in the literature mainly investigated the seam performance of woven fabrics, and few studies focused on knitted fabrics. However, knitted fabrics are more susceptible to damage during sewing. The literature search revealed that no systematic study has been conducted to investigate and compare the effects of repeated washing cycles on the seam quality of knitted fabrics with specific raw materials and weights. Our results show that fabric composition is an important factor in the selection of sewing thread. The sewing threads that give the best results before and after washing are different for different fabric types. In addition, we find that higher stitch density has a positive effect on seam strength, while it has a negative effect on seam pucker. Based on the above explanation, changing some parameters may have a positive effect on one element of seam quality while having a negative effect on another. For this reason, it is important that the parameters are properly selected according to the specific end-use of the apparel products.

Perspectives

We hope that knowledge of the various factors affecting seam performance will help manufacturers to improve production performance and produce high-quality seams.

Dr. Esra Zeynep YILDIZ

Ege Universitesi

Read the Original

This page is a summary of: The Effect of Sewing Parameters and Washing Cycles on Seam Performance of Single Jersey Fabrics, Journal of Testing and Evaluation, August 2022, ASTM International,

DOI: 10.1520/jte20220111.

You can read the full text:

Contributors

The following have contributed to this page