What is it about?

This study explores a method to enhance the performance of transition metal oxide catalysts for water splitting by optimizing their structure and composition. The focus was on creating mesoporous mixed metal oxides with a specific composition (Mn0.1Fe0.1Ni0.3Co2.5O4) using a one-step impregnation nanocasting technique. It was found that low-temperature calcination (150–200 °C) in a semi-sealed container helps maintain porosity, particle size, and elemental homogeneity. It was found that calcining the catalyst at 170 °C produced the best results, showing the lowest overpotential (335 mV at 10 mA cm−2), highest current density (433 mA cm−2 at 1.7 V vs. RHE), and excellent stability over 22 hours. The method's effectiveness was enhanced by controlling humidity through pre-drying. Additionally, using inexpensive, commercially available silica gel as a hard template produced similar performance results.

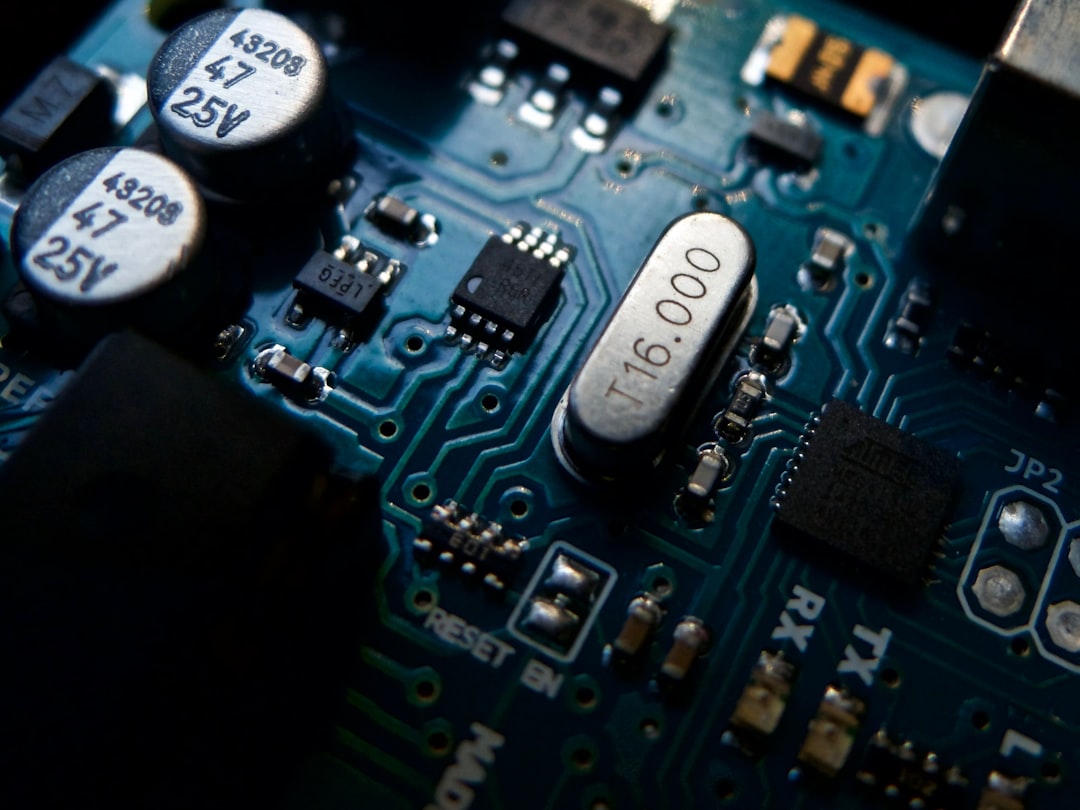

Featured Image

Photo by Denes Kozma on Unsplash

Why is it important?

This approach represents a significant advance in the cost-effective large-scale production of complex multi-metal oxides for catalytic applications in water splitting.

Read the Original

This page is a summary of: Low-Temperature controlled synthesis of nanocast mixed metal oxide spinels for enhanced OER activity, Journal of Colloid and Interface Science, May 2024, Elsevier,

DOI: 10.1016/j.jcis.2024.01.056.

You can read the full text:

Contributors

The following have contributed to this page